What is Variable Speed Driver (VSD) technology?

Modern, energy efficient compressed air systems, as well as individual analysis of compressor systems, can bring about potential energy savings of 30 to 50 %.

Over 80% of a compressor’s lifecycle cost is taken up by the energy it consumes.

In almost every production environment, air demand fluctuates depending on different factors such as the time of the day, week or even month.

Extensive measurements and studies of compressed air demand profiles show that many compressors have significant variations in air demand.

To cut your energy costs, Leeair provides the application “Variable Speed Driver technology” in the compressed air industry.

The design of Leeair. L-series machine ensures high efficiency over all the range of working condition, with a wider range of frequency conversion from 30% to 100%.

The air output variation is directly proportional to actual power consumption, approximately to energy efficiency curve under ideal status.

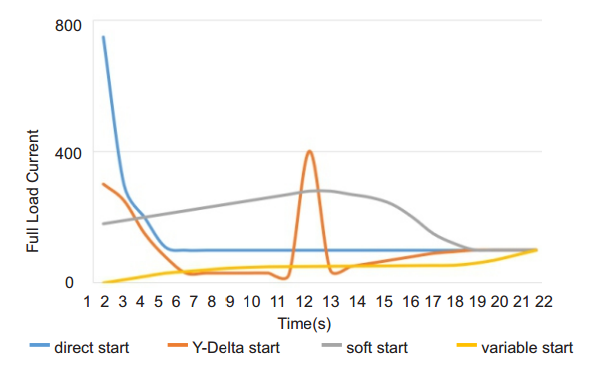

Variable frequency soft start, No current peak phenomenon

No current peak during start up unlimited starting and stopping. Saving in electrical installation : smaller breakers, fuses, transformers and cables

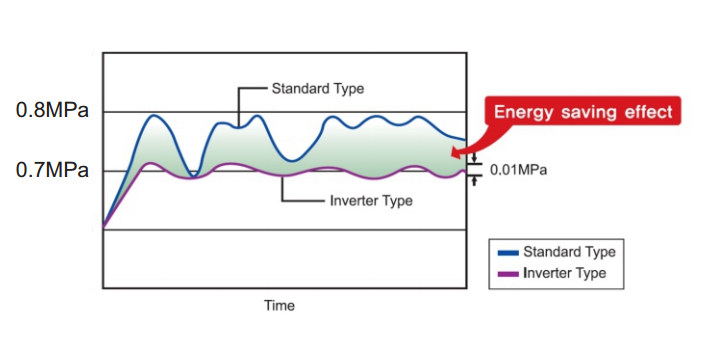

Comparison of energy saving between Standard type and inverter type

Through constant voltage control under 0.01 MPa, it can produce the required accuracy of compressed air and it leads to achieve more energy saving.

Permanent Magnet Motor

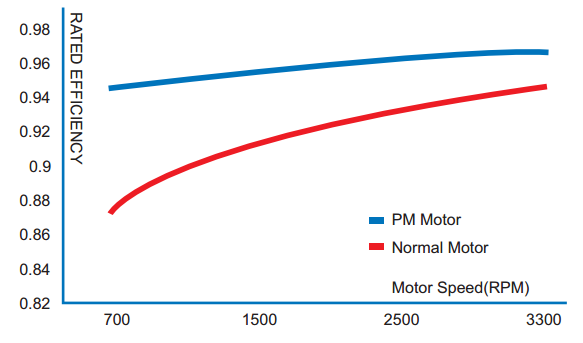

Test result of the efficiency and power of the permanent magnet motor at different speeds.

Permanent magnet motor provides much longer durability, applying good quality permanent magnet (NdFeB) which does not loss the excitation even at 180℃.

The motor speed regulation range is wide, the precision is high, the air volume adjustment range is wider.

Leeair. L-series Permanent Magnet Motor

Eliminate the inefficient conversion process from unload to full load.

Applied permanent magnet motor, energy saving is 6 to 7 % higher compared to other ordinary inverter compressor.

Maintain the fluctuation pressure under 0.01 MPa in the process line, reduced the average working pressure.

Soft start method improved current balance of motor and prevented shock of current.

Variable Frequency Control with Permanent Magnet Motor

PM Motor Type compressor with variable frequency control (Inverter Control) is available to save energy from 6 to 7% more than Ordinary Inverter Type Compressor.

Energy-saving condition

Permanent magnet motor can maintain high motor efficiency at low speed.

When the air consumption is small, it has obvious advantage of saving energy.

How much it can save?

The energy consumption rate of air compressor in a factory could be more than 40~80 % from whole energy consumption, this L-series can significantly reduce energy consumption. It can control production of air volume by variable speed control in accordance with actual demand of compressed

L100 Energy saving(30% Unloading)

L100PS energy saving: USD21,000/Year (38%saving)

L100PE energy saving: USD23,300/Year (44%saving)

Leeair. l-series Variable Speed Drive technology closely matches the air demand by automaticallyadjustingthe motor speed. Combinedwith the innovativedesign of the PM (Permanent Magnet) motor, this results in average energy savings of 44% and an average cut of 35% in the lifecycle cost of a compressor

Intelligent controller

- Simple and intelligent interface for ease of operation

- Remote start / stop control

- 20 recording alarm / trip history

- Password protection against unauthorized operation

- Capacity of sequencer control mode for maximum 16 machines. External sequencer is unnecessary.

- Real time compressor status displayed with LCD indicator.

- Record malfunction data for ease of maintenance

- MODBUS communication protocol with capacity of connecting to all type of central monitoring system.

- Warning for consumable parts replacement

Why use AIRMATICS™ ?

- Industry 4.0 ready

- Fully interoperable

- Brand agnostic: AIRMATICS™ can be integrated within any air compressor eco-system – regardless of manufacturer

- Reduces energy bills attributable to air compressors by up to 30%

- Minimises sustainability footprint by reducing carbon emissions

- Maximises performance and creates efficiencies

- Reduces wear and tear: IoT capability and continual live communication between air compressor and control centre means performance never exceeds system requirements at any given moment

- Transparent and easy-to-use reporting: The AIRMATICS™ interface is intuitive and makes gaining insights, data and reporting accessible regardless of location

- Decentralised decision-making: AIRMATICS™ automatically makes the best decisions for your air compressors’ functionality and usage

- Fully secure

- Reduce time spent by workforce on manual diagnostics and resolution

- Big data helps businesses make big decisions about their air compressor systems